Comparative Measuring

In today's world, precision and accuracy are critical in every aspect of life. From engineering to cooking, from medicine to construction, every industry requires accurate measurement. Comparative measuring is a technique that has revolutionized the way we measure and compare objects, allowing us to achieve maximum accuracy and precision.

Pain Points in Comparative Measuring

One of the biggest issues in traditional measuring techniques is the lack of precision. While it is possible to measure an object accurately, it is difficult to compare it to another object. This issue is particularly problematic when measuring small parts or objects that have complex geometries. Another issue is the time it takes to measure each object and to compare them manually.

Target of Comparative Measuring

The main target of comparative measuring is to measure and compare objects accurately and quickly. It allows for the measurement of complex geometries and small parts with high precision. It also helps to reduce human error, resulting in more accurate measurements.

Main Points on Comparative Measuring

Comparative measuring is a technique that involves measuring an object against a reference object to determine the difference between the two. This technique allows for quick and accurate measurement of complex geometries and small parts. It is typically done using comparative measuring gauges, which are specialized tools used to compare objects.

Using Comparative Measuring in Practice

As a machinist, I have been using comparative measuring for many years. One of the most common applications of this technique is when measuring the diameter of a hole. By comparing the hole to a reference pin, I can quickly and accurately measure the diameter of the hole to within a few microns.

Another application of comparative measuring is when checking the roundness of a part. By comparing the part to a reference sphere, I can quickly determine if the part is round or not. This technique is particularly useful when working with parts that have a complex geometry.

Comparative Measuring Gauges

Comparative measuring gauges are specialized tools used to compare objects. There are many different types of comparative measuring gauges, including dial indicators, micrometers, and height gauges. These gauges are designed to be accurate to within a few microns, allowing for quick and precise measurements.

How Comparative Measuring Works

Comparative measuring works by measuring an object against a reference object. The reference object is typically a standard or a master gauge, which is known to be accurate. By comparing the object to the reference object, any differences between the two can be measured and recorded. This technique allows for quick and precise measurements of objects with complex geometries and small parts.

The Benefits of Comparative Measuring

There are many benefits of using comparative measuring, including:

- Quick and accurate measurement of complex geometries and small parts

- Reduced human error

- Time-saving

- Improved quality control

Question and Answer

Q: How accurate is comparative measuring?

A: Comparative measuring is typically accurate to within a few microns.

Q: What are the advantages of comparative measuring over traditional measuring techniques?

A: Comparative measuring allows for quick and accurate measurement of complex geometries and small parts. It also reduces human error and improves quality control.

Q: What types of comparative measuring gauges are available?

A: There are many different types of comparative measuring gauges, including dial indicators, micrometers, and height gauges.

Q: Why is comparative measuring important in manufacturing?

A: Comparative measuring is important in manufacturing because it allows for the quick and accurate measurement of complex geometries and small parts, which is essential for maintaining quality control.

Conclusion of Comparative Measuring

Comparative measuring is a valuable technique that allows for the quick and accurate measurement of complex geometries and small parts. It is an essential tool in many industries, including manufacturing, construction, and engineering. By using comparative measuring, we can achieve maximum precision and accuracy, resulting in improved quality control and reduced human error.

Gallery

Comparative Measuring In Perspective | New Masters Academy

Photo Credit by: bing.com /

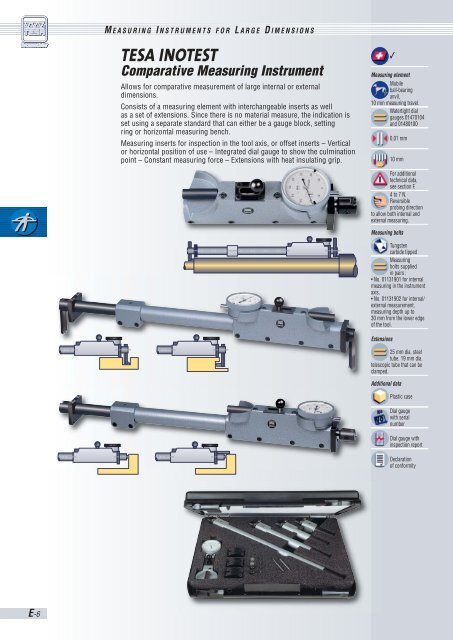

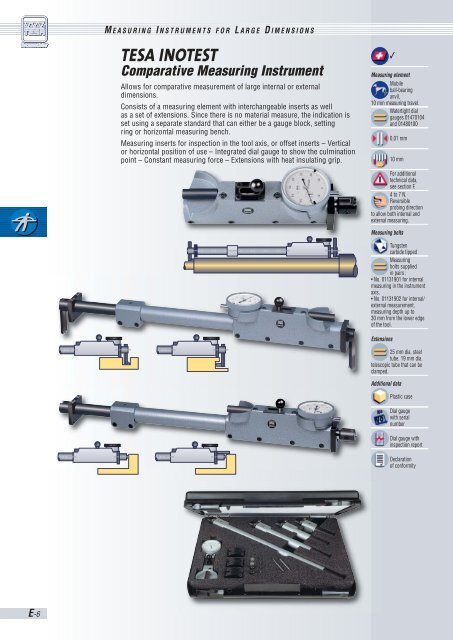

TESA INOTEST Comparative Measuring Instrument

Photo Credit by: bing.com /

Comparative And Measuring Gauges | Tac Tools

Photo Credit by: bing.com / comparative

Comparative Measuring Gauges | Swiss Instruments Limited

Photo Credit by: bing.com / measuring comparative gauges

Sight-Size Versus Comparative Infographic | Sight-Size

Photo Credit by: bing.com / comparative